How To Reduce Generator Installation Costs

Factors Impacting Generator Installation Costs

This article explores the various factors impacting installation costs for any standby generator installation. Installation costs will vary with each generator model and not all generator installations are the same.

Let’s look at some of the major factors impacting generator installation costs.

Generator Installations Require Two Contractors

For LP and natural gas generators, you'll need:

- Licensed Electrician – Must have proven experience installing standby generators to handle all electrical work

- Licensed Plumbing or Mechanical Contractor – Required to install the gas line

Both contractors will pull permits if required by local code enforcement.

The Turnkey Installation Advantage

Experienced generator installers typically have relationships with licensed plumbing contractors and can offer a turnkey installation quote that includes both electrical and plumbing work.

Key benefits of turnkey installations:

- One point of contact for the entire project

- No finger-pointing between contractors if issues arise

- Single contractor responsible for making everything right

- Experienced installers make fewer mistakes and can offer routine generator service post-installation

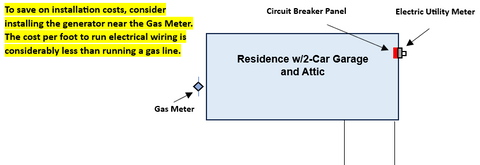

Generator Placement for Natural Gas and LP Generators

Placement of your standby generator has the biggest impact on installation costs.

Natural Gas Generators

Best-case scenario: Gas and electric meters on the same side of the house

- Shorter gas and electrical line runs

- Lower material and labor costs

- Minimal installation expenses (shorter gas lines, less wiring and labor)

Installation tips to minimize costs:

- Place the generator near the gas meter (running electrical wiring is less expensive than gas lines)

- Electrical wiring can be run through the attic or under homes with conventional foundations

- Most local codes allow natural gas lines to run above ground and attached to the side of the house (least expensive method)

- Burying the fuel line requires trenching, which adds labor and equipment costs

LP (Propane) Generators

Placement requirements:

- Install generator on the same side of the house as the LP tank

- Local codes typically require the generator to be at least 10 feet from the LP tank

- No plumbing contractor required—most LP service providers can install the fuel line from tank to generator

Is a Concrete Pad Required?

Air-Cooled Generators

Standard installation:

- Most come with a preformed mounting pad attached

- Set on a bed of rocks and level ground

- Concrete pad not required but preferred by many homeowners

Liquid-Cooled Generators

Concrete pad required:

- These generators are considerably larger

- Allow an additional 3-6 inches around the generator when sizing the pad

- Check dimensions on the generator's Specifications Sheet (available on the Buckeye Power Systems website)

Conduit Planning for Concrete Pads

If generator wiring will enter from underneath:

- Trench conduit for high and low voltage lines before pouring concrete

- Provide conduit stub-ups within the pad dimensions

- Consult generator specifications and installation manual for precise stub-up locations

- Install conduit stub-ups prior to pouring concrete

Building a New Home? Save Big on Installation Costs

Take advantage of construction to significantly reduce generator installation expenses:

During the build process:

- Purchase the Automatic Transfer Switch (ATS) during construction

- Have your builder's electrician install the transfer switch while wiring the new home

- Pour the concrete pad (if required or desired) while doing other concrete work

-

Run the fuel line and shut-off valve from the gas meter to generator location using the builder's plumbing contractor

- Provide the plumber with the BTU output of your generator (found in the specification sheet)

Result: The only remaining task for a generator installer is connecting the generator to the transfer switch—all other work is complete at substantial savings compared to retrofitting an existing home.

Choosing the Right Installer

Selecting the right installer is the most important aspect of your standby generator project.

What to Look For

Hire an experienced generator installer, preferably an authorized dealer:

- Authorized dealers can resolve warranty issues directly

- Establish an ongoing relationship for post-installation routine generator service

- Oil and filter changes

- Generator testing

- Warranty repairs

Experience Matters

Our Memphis, Tennessee shop has been installing standby generators for residential and industrial customers for over 20 years. Every few months, we receive calls to correct installation errors made by experienced electricians who lack generator-specific experience.

Bottom line: Experience with standby generators truly matters.

Overall Project Costs: What to Expect

When budgeting for a professionally installed standby generator, use this rule of thumb:

Installation costs typically equal the cost of generator equipment

Cost Examples

Air-Cooled Generator:

- Generator and ATS gear: $7,500

- Total project estimate: $15,000

Liquid-Cooled Generator: Higher installation costs due to:

- Required concrete pad

- Larger fuel lines and wiring

- Additional labor for multiple transfer switches

- Special equipment needed to move and position the generator

Note: While not always exact, this rule of thumb is fairly accurate for most installations.

Ready to Get Started?

Contact Buckeye Power Systems for expert generator sizing assistance. Our experienced team will ensure your standby power system is sized correctly and shipped to your home and ready for installation. Our team will also help identify qualified installers in your area to complete a turnkey installation. Call us today at 901-379-8097.

Coming up next, we explore Generator Sizing and Load Management issues.