Top 5 Reasons Why Your Home Standby Generator Might Fail to Start

A Homeowner's Guide to Avoiding the Dark

Picture this: A storm knocks out power to your neighborhood, but you're confident because you have a standby generator. You wait for it to kick on automatically... but nothing happens. You're left scrambling with flashlights and candles, wondering why your expensive backup power system has failed you.

Unfortunately, this scenario happens more often than you'd think. Power outages are becoming increasingly common due to aging power grids, severe weather, and inadequate maintenance of utility infrastructure. While your standby generator is designed to keep your lights on, air conditioning running, and refrigerator humming during outages, these mechanical systems can fail – often at the worst possible moments.

The good news? Most generator failures are preventable with proper maintenance and awareness. Here are the top five reasons your home standby generator might fail to start, and what you can do to prevent each one.

1. Dead Battery: The #1 Culprit (Over 50% of All Failures)

The Problem: Your generator's battery is dead or dying, preventing the engine from cranking when you need it most.

Just like your car, your standby generator relies on a battery to start the engine. Battery failures account for roughly half of all generator startup problems, making this the most common issue homeowners face.

Why This Happens:

- Batteries naturally lose capacity over time

- Battery chargers can malfunction or get unplugged

- Circuit breakers protecting the charging system may trip

- Extreme temperatures affect battery performance

How to Prevent It:

- Replace your generator battery every 2 years (industry standard)

- Check monthly that the battery charger is plugged in and the circuit breaker hasn't tripped

- Consider the cost: A $100-200 battery replacement is much cheaper than an emergency service call that could cost $300-500 or more

- During your annual service, have the technician test the battery charging system

Quick Check: Look for a small light on your battery charger – it should be green or show "charging" status. If it's red or off, investigate immediately.

2. Skipping Regular Maintenance: A Recipe for Disaster

The Problem: Your generator hasn't received proper professional servicing, leading to multiple small issues that prevent startup.

Many homeowners treat their generator like a set-it-and-forget-it appliance. However, these are sophisticated machines with engines that require regular maintenance just like your car.

Why This Happens:

- Oil becomes dirty or low, causing engine damage

- Air filters clog with debris

- Spark plugs wear out

- Small problems go undetected and compound over time

How to Prevent It:

- Schedule annual professional service with a qualified technician

- Change oil and filters annually or every 200 engine hours of operation

- After extended outages (a week or more of running), schedule additional service even if it was recently maintained

- Keep a maintenance log to track service dates and hours of operation

Reality Check: Professional maintenance typically costs $400-$600 or more annually, but prevents thousands in emergency repairs while also ensuring your generator works when needed.

3. Wrong Switch Position: A Simple but Critical Mistake

The Problem: Your generator is switched to "MANUAL" mode instead of "AUTO" mode.

This might sound too simple, but it's surprisingly common. When service technicians work on your generator, they switch it to manual mode for safety. Sometimes they forget to switch it back to automatic mode when finished.

Why This Happens:

- Technicians forget to return the switch to AUTO after service

- Homeowners accidentally change the setting

- Family members unfamiliar with the system make adjustments

How to Prevent It:

- Always check the generator status after any service call

- Learn how to check your generator's mode using these methods:

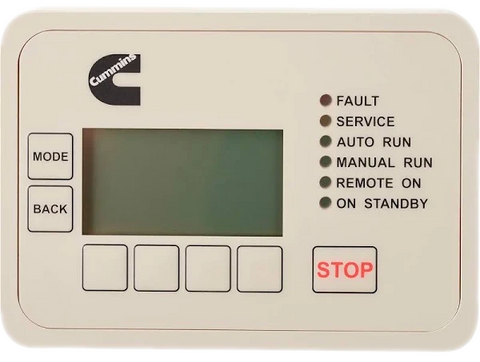

1. Physical Check: Open the generator's access panel and look at the display screen for "AUTO RUN" and "ON STANDBY"

2. Indoor Monitor: If you have a wall-mounted remote monitor, check the status display

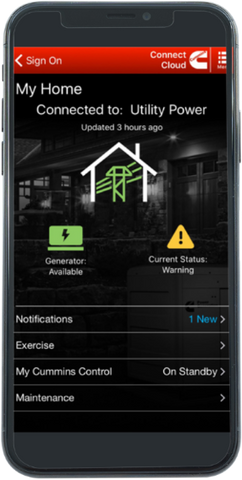

3. Smartphone App: When your Cummins generator is connected to WiFi, real-time status alerts are sent to your smartphone or tablet. The Cummins ConnectCloud app is free to download and there are no ongoing monitoring fees.

Pro Tip: Set a monthly reminder to check your generator's status, just like you'd check smoke detector batteries.

4. Cooling System Problems: When Your Generator Overheats

The Problem: Worn hoses, loose belts, or clogged radiators prevent proper engine cooling, causing automatic shutdown or failure to start.

Your generator's engine produces significant heat during operation. The cooling system must function perfectly, or the engine will overheat and shut down automatically to prevent damage.

Why This Happens:

- Rubber hoses crack and leak over time

- Drive belts stretch and slip

- Radiator cores become clogged with leaves, dirt, or debris

- Coolant becomes dirty or degrades

How to Prevent It:

- Keep the area around your generator clean and free of debris

- Trim vegetation at least 3 feet away from the unit

- During monthly checks, visually inspect for obvious leaks or damage

- Have cooling system components inspected during annual service

- Never block air vents or exhaust outlets

Warning Signs: Look for coolant puddles under the generator, unusual noises during operation, or frequent shutdowns during testing.

5. Transfer Switch Issues: The Hidden Component That Controls Everything

The Problem: Your Automatic Transfer Switch (ATS) – the device that switches your home from utility power to generator power – has mechanical problems.

The transfer switch is like the brain of your backup power system. When it detects a power outage, it signals the generator to start and switches your home's electrical load. If this component fails, your generator might start but won't power your home.

Why This Happens:

- Moving parts can seize from lack of use

- Dust and debris interfere with operation

- Electrical contacts become corroded

- Older units may have obsolete parts that are difficult to replace

How to Prevent It:

- Include transfer switch inspection in your annual service

- Test your generator monthly to keep components moving

- Keep the transfer switch area clean and dry

- When replacing an old transfer switch, ensure it's properly matched to your generator model

Important: Generic transfer switches may work with your generator but often lack communication features that provide status updates and enhanced functionality.

Bonus Tip for Diesel Generator Owners: Fuel Contamination

The Problem: Water in your fuel tank can damage engine components and prevent startup.

Water is heavier than diesel fuel and settles at the bottom of the tank where it can be drawn into the engine, causing expensive damage.

How to Prevent It:

- Keep your fuel tank as full as possible (less air space means less condensation)

- Add fuel stabilizer as recommended by the manufacturer

- Have fuel samples tested during annual service

- Watch for signs like cloudy fuel or water separation in fuel samples

Red Flag: If your fuel gauge doesn't drop during regular exercise cycles, you may have a faulty fuel level sensor – another item to address and check during routine service.

Your Action Plan: Keeping the Lights On

Monthly Tasks (5 minutes):

- Check that generator is in AUTO mode

- Verify battery charger is plugged in and functioning

- Clear any debris from around the unit

- Listen to the weekly exercise cycle for unusual sounds

Annual Tasks:

- Schedule professional service with a qualified technician

- Replace the battery every 2 years

- Review and update your maintenance log

- Test the transfer switch operation

After Any Service Call:

- Confirm the generator is back in AUTO mode

- Test the system if possible

- Update your maintenance records

The Bottom Line: Prevention Pays

Regular maintenance by a qualified professional is your best insurance against generator failure. While it requires an annual investment of a few hundred dollars, this cost pales in comparison to the expense and inconvenience of being without power during an outage – or dealing with emergency repairs that can cost thousands.

Remember, your standby generator is there to provide peace of mind during stressful times. Don't let preventable maintenance issues turn your backup power system into another source of stress. A little attention throughout the year ensures your generator will be ready when you need it most.

Ready to ensure your generator won't leave you in the dark? Contact a qualified service provider in your area to schedule your annual maintenance or address any concerns with your current system.