Cost-Saving Options on Generator Placement Location

Installation of a standby generator fueled by natural gas or LP will require two contractors. One contractor handles the electrical while a plumbing or mechanical contractor is required for running a gas line to the generator. Installation costs will range higher when a generator is placed away from the home’s electrical and gas supply sources.

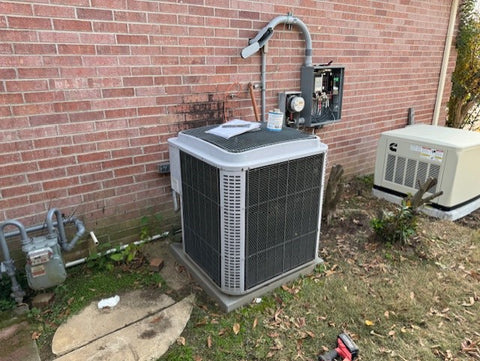

The ideal installation scenario for a low-cost installation is when the home’s electric and gas meters are on the same side of the house and the generator is installed adjacent to these meters. The image below illustrates a lower cost installation because the generator is positioned near the gas and electric meters.

Not all installations are ideal, and in many cases, the gas meter is on one side of the house while the electric meter is on the opposite side.

The most economical location for the generator will be dictated by comparing costs to run electrical wiring vs. costs to run a fuel line. The cost per foot to run a fuel line from the gas meter to the generator is significantly higher than the cost per foot to run electrical wiring. Thus, it makes better economic sense to install a generator close to the fuel source. Electrical wiring can be run through the attic or under homes with a conventional foundation.

The gas line to a standby generator must be on a dedicated pipe. The fuel line to the generator cannot be shared with other gas appliances because fuel pressure changes can disrupt the operation of the generator. Make sure the fuel line to the generator is on a separate dedicated pipe from the gas meter or LP tank to the generator.

When considering a location for a standby generator fueled by natural gas, you will minimize installation costs by choosing a location closer to the gas meter. For generators fueled by LP, position the generator close to the LP tank but most local codes require a 10–15-foot distance between the LP tank and the generator. If it is possible to position the LP tank at or near the electric meter, less electrical wiring and labor is required, minimizing installation costs.

Diesel generators typically come with a subbase fuel tank negating the need for a fuel line. So, position the generator closer to the electric meter to keep installation costs down.

Now that we have selected the most cost-effective location for the generator, our next article will explore other Factors Impacting Generator Installation Costs and tips on keeping these costs at a minimum.

Click here to read the next article now.